Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Customized

Brand: XGR

Certification: Other

Temperature: High Temperature

Pressure: High Pressure

Application: Oil&gas Industry

Connection: Other

Material: Cobalt Based Alloy

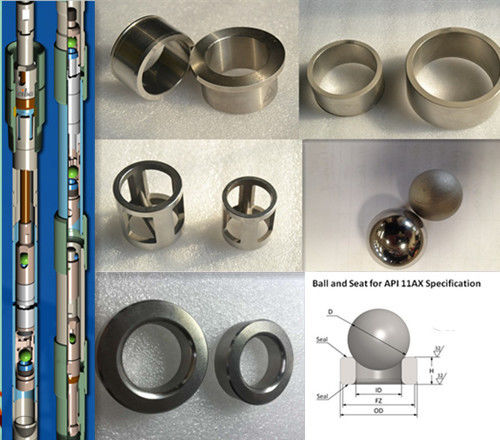

Product Name: Oil And Gas Industry Cobalt Based Alloy Globe Valve Cage

Properties: Wear And Corrosion Resistance

Key Word: Cages For Pump

Type: Size 1.25" To 2.75"

Fittings: Valve Seat, Ball, Bushing

Brand: Cobalt Based Alloy

Production Process: Investment Casting,forging

Version: Customized Accetable

Packaging: Normal export package ,cartons and plywood case

Productivity: 5000 pieces per month

Transportation: Ocean,Land,Air

Place of Origin: Shenyang,Liaoning,China

Supply Ability: 5000 pieces per month

Certificate: IOS9001

Port: Dalian Port,Qingdao Port,Shanghai Port

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CIP

Cobalt Chrome Alloy flapper type float Valve Cage

Production process :

1. Investment casting process

Different volume of furnaces, the order quantity can be very flexible.

1. Machining

CNC, lathing, drilling, milling, grinding, wire cutting, polishing

Technical requirements :

Dimensions, drawings, tolerance, surface finish, radius, as your demands.

Let us know your demands, we`ll feedback you within 2 hours.

Valve cages spesifications

St.6 valve cage 1.25", 22g/pc

St.6 valve cage 1.50", 40g/pc

St.6 valve cage 1.75", 80g/pc

St.6 valve cage 2.00", 118g/pc

St.6 valve cage 2.25", 142g/pc

St.6 valve cage 2.75", 264g/pc

Chemical compositions and properties (%)

| Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | P | S | Density (g/cm3) | Hardness (HRC) |

| ST 3 | 2.0-2.7 | 1.0 | 1.0 | 29-33 | 3.0 | | 11-14 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.55 | 51-55 |

| ST 6 | 0.9-1.4 | 1.0 | 1.5 | 27-31 | 3.0 | 1.5 | 3.5-5.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.35 | 38-44 |

| ST 12 | 1.1-1.7 | 1.0 | 1.0 | 28-32 | 3.0 | | 7.0-9.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.40 | 44-49 |

| ST 20 | 2.2-3.0 | | 2.0 | 30-34 | 3.0 | 1.0 | 14-18 | Bal. | 3.0 | ≤0.05 | ≤0.05 | 8.65 | 53-59 |

Shipment and package :

Realted products :

Product Features

1. High temperature resistance

The strength keeps stable up to 800℃ and it can even momentarily used at 1200℃.

2. Wear resistance

Due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a

CoCr alloy matrix, it has exceptional wear and galling resistance.

3. Corrosion resistance

This exellent and lovely property allows this kind of material parts to be used in oil&gas, slurry, acid liquid and any other mediums.

| For you | ||

| We Are | We Have | We Can |

| Professional Manufacuturer | Plenty Production Capacity | Produce Parts Meeting Customer`s Demands |

| Reputed Global Supplier | 10 years Exporting experience | Easy Communication |

| Material Solution Expert | Materials Science Background | Provide Material Choice Solution |

Why Choose us?

-Our faith is that the quality and customer's demands are always the first important thing for everyone in our company.

1. 15 years in producing Cobalt Alloy parts and 10 years exporting experience.

2. Providing professional solutions.

3. Our own R&D team has professional backgroun and excellent innovation ability.

4. Drawing designed ability.

5. Customized producing.

6. Small quantity is acceptable.

7. Quick feedback and good English communication.

Product Categories : Cobalt Chrome Alloy Valve Cage

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.