- Cobalt Chrome Alloy Bushings

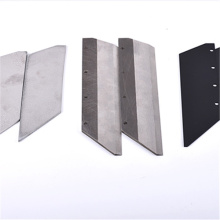

- Cobalt Chrome Alloy Fiberglass Cutter Blade

- Cobalt Alloy Hot Extrusion Dies

- Cobalt Chrome Alloy Saw Tips

- API VII Series Valve Seat And Ball

- Cobalt Chrome Alloy Valve Cage

- The Stator And The Rotor

- Dental Soft Alloys

- Cobalt Chrome Alloy Impeller

- Cobalt Chrome Alloy Valve Seat

- Cobalt Chrome Alloy Sealing Ring

- Thermocouple Protection Tube

- Cobalt Chrome Alloy Nozzle

- Cobalt Chromium Alloy Rod

- Cobalt Chromium Alloy Tube

- Cobalt Chromium Alloy Sheet

- Spinning Plate

- Copper Tungsten Alloy

- Silver Tungsten Alloy

- Grinding Wheel

- Stainless Steel

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.